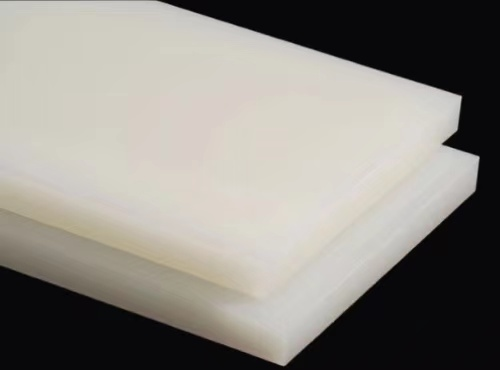

PVDF sheet is made of PVDF resin after high temperature extrusion into a sheet, is a very pure polymer. It is white/dark grey. It contains no additives such as UV stabilizers, heat stabilizers, softeners, lubricants or flame retardants. Due to its chemical inertness, PVDF rarely reacts with any medium.

High temperature resistance (can work at 172 degrees), excellent resistance to chemical corrosion and hydrolysis, outstanding resistance to UV and weather. High mechanical strength, good rigidity, good creep resistance, good sliding and wear resistance, inherent low flammability, good electrical insulation performance.

Characteristic:

It has higher stiffness and bearing capacity than the similar PTFE, but the smoothness and electrical insulation are less. It has high strength and toughness at low temperature and can self-extinguish. Its operating temperature is between -60℃ and +150℃. PVDF is stable to chloride, bromide and energy rays. At high temperature, both ester and ketone solution can cause erosion.

Application:

Semiconductors, liquid crystal associated devices and other electronic industry, chemical equipment, food processing machines, packaging machines of various parts, pipes, seals, pump components, rotary disks, valves, slides, etc. Suitable for petrochemical, chemical, metallurgy, food, paper, textile, pipeline, sealing parts, pump parts, rotary disc, valve, stop valve, extraction centrifuge, embedded gear, pipe connection, slide rail. Component manufacturing for the pharmaceutical and atomic industries.

Property Parameter:

| Property | Value | Norm |

|---|---|---|

| Density (g/cm³) | 1.77 | ISO1183 |

| Water absorption (%) | 0.04 | DIN53495 |

| Elongation at break (%) | 28-40 | ASTM D882 |

| Tensile strength (MPa) | 46 | ISO527 |

| Bending strength (MPa) | 80 | ISO178 |

| Elasticity Strength (MPa) | 2000 | ISO527 |

| Impact strength (no notch) (kJ/m²) | 252 | ISO179 |

| Impact strength (notch) (kJ/m²) | 22 | ISO179 |

| Shore Hardness D | 78 | DIN53505 |

| Flame retardant rating | V-0 | UL94 |

| Temperature range | -30-150 |

Kindly note:

PVDF sheet, burning contains fluorine smoke, not easy to bond.