Contents

Expanded PTFE sheet is pure white, which is made of 100% PTFE polytetrafluoroethylene through special processing. It has flexibility, tensile strength, creep resistance, high and low temperature resistance, corrosion resistance, cold flow resistance, Anti-aging, non-toxic and non-polluting. The interior is composed of countless homogeneous, fine, soft and strong multi-directional fibers, with a unique high-density fiber structure. After compression, the fibers will entangle with each other and become a more compact and uniform structure. It is airtight, watertight, and leak-proof, and can maintain the required sealing effect even in harsh corrosive environments and high temperatures.

Extremely strong chemical corrosion resistance

It does not react with any chemical substances except molten alkali metals, free fluorine, tertiary nuclear and other few chemical substances. It can be applied to all sealing occasions within the allowable range of temperature (-260°C – + 260°C), which will greatly reduce the quality and quantity of seals.

Seals rough surfaces

Has a unique ability to conform to the shape. Creates a good seal on rough or damaged flanges without much added pressure.

Easy to cut and install

Gaskets can be cut into any shape by mechanical stamping or manual cutting, which makes your work easier.

Good creep and cold flow resistance

The unique high-density fiber structure makes it have strong creep resistance. Very mechanically stable due to the absence of any binders and additives.

Characteristics:

- 100% pure PTFE material

- Excellent ability to adapt to the performance and molding;

- High resistance tensile strength, creep resistance;

- High temperature resistance, corrosion resistance;

- Anti-cold, anti-aging

- With excellent flexibility;

- Good sealing property

- Highly compressible and resilient

- Multidirectional uniform and highly fibrinalized microstructure

- Resistance to creep and cold flow.

- Not affected by ordinary chemicals, corrosion resistance, high temperature resistance and weather resistance.

- PH ranges from 0 to 14

- Pollution-free, non-toxic.

- Compliance with FDA requirements (FDA 21 CFR177/1550)

- Use temperatures from -450°F to +500°F and up to +600°F for short periods

- Easy to cut and install, easy to install

- Low compression load of seal

- Seal rough or damaged flanges to achieve good sealing effect

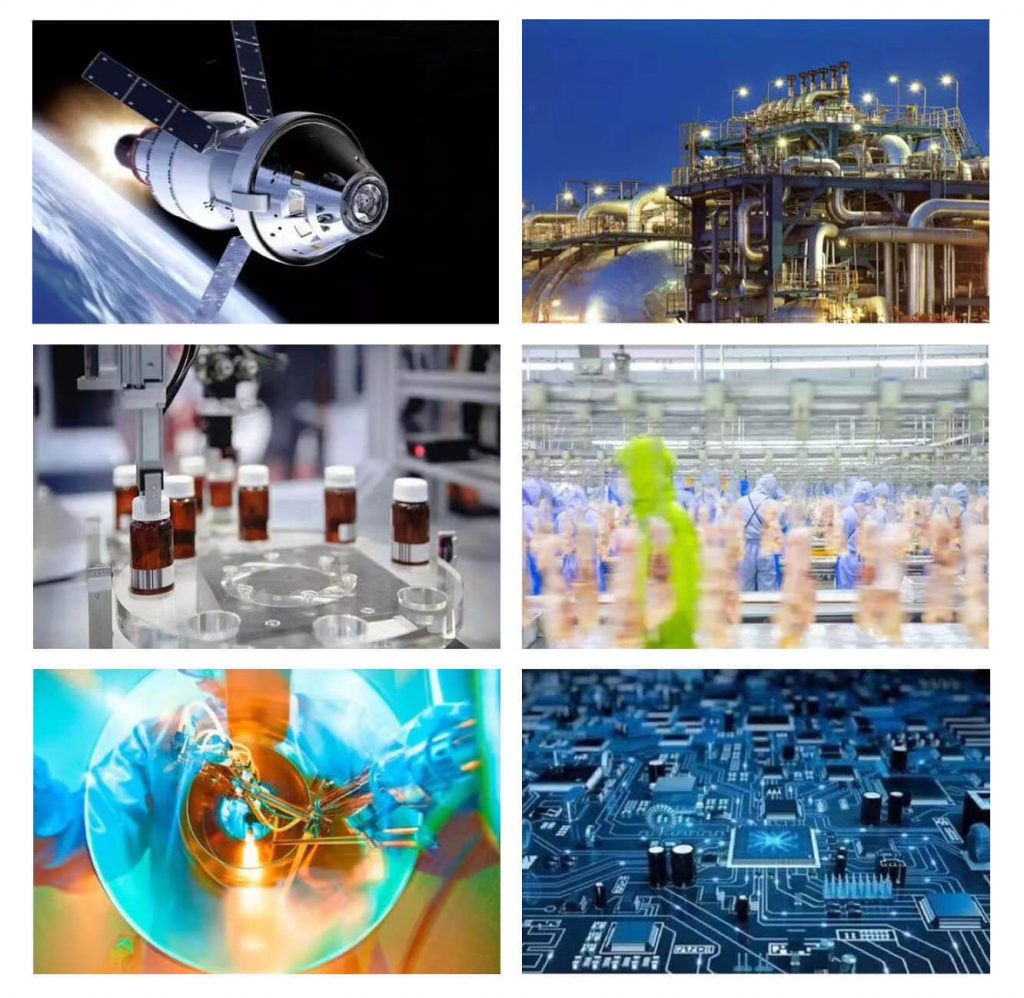

Application:

Used as a sealing material for various flanges. It can be used in chemical industry, food industry, pharmaceutical industry, semiconductor industry, aerospace industry, petrochemical industry, paper industry, shipbuilding industry and medical equipment industry, as well as the need of special sealing environment.

- Aerospace

- Petrochemical

- General Chemical

- Pulp and Pape

Advantages:

- Good chemical resistance

- Resistance to cold flow

- Excellent mechanical strength

- Reliable sealing

- Flexible & easy cutting

- Clean and non-toxic.