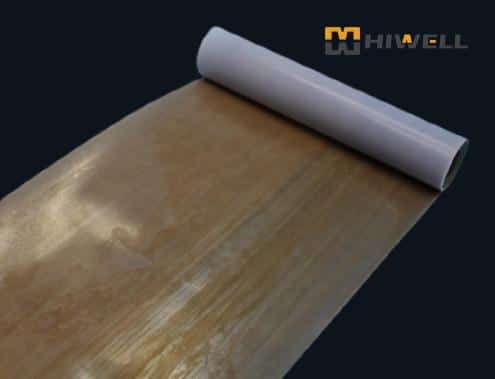

PTFE(Teflon) cutting film and cutting board products are subjected to single-sided or double-sided surface treatment to make it tacky and can be coated with ordinary adhesives.

The chemical etching treatment changes the surface finish by altering the polymers properties, making them very suitable for bonding with most adhesives, such as epoxy resins, polyurethanes, etc.

The process steps of treating PTFE products with sodium naphthalene treatment solution are as follows:

Step 1: The first has skived PTFE products, including PTFE sheet or PTFE film with acetone or alcohol cleaning, remove the surface oil and dirt;

Step two: At room temperature, dip clean PTFE products into the prepared sodium naphthalene treatment solution for 1 to 10 minutes and then take out;

Step 3: First clean with normal temperature water, clean in 90℃ hot water, remove NaH and NaOH and other residues, until the surface of the PTFE is dark brown, dry or dry in the oven, and then reroll;

Step 4: Wrap with black masking film for later use.

Polytetrafluoroethylene(PTFE) sodium treating agent can be used for surface treatment of PTFE pipe, sheet, film and filled PTFE, etc. Main performance appearance: black paste shear strength: 9.8mpa treated PTFE film surface resistance: compared with the untreated film reduced by 1-2 power. Storage life (sealed) more than 1 year. After treatment, the surface of PTFE is not resistant to ultraviolet light, and the treatment effect will be lost under long-term irradiation of strong ultraviolet light. Therefore, after the treatment of PTFE, if not timely bonding, should be protected from light.

Usage Wipe the surface of treated PTFE clean with cotton dipped in acetone, air dry, and stir the treating agent well with a glass stick. For small area treatment, use a glass stick to dip an appropriate amount of treatment agent on the surface of the plastic to be treated, turn the glass stick, and the treatment agent on the stick is evenly coated on the plastic surface; When brushing, use polyethylene brush (no general brush) and brush in one direction without returning. The thickness of treating agent should be controlled at about 0.5 mm. For small plastic parts, if the whole processing is allowed, the parts can be immersed in the treating agent. The PTFE treated in this way has uniform surface color and good effect. All of the above treatment methods, treatment time is 1-5 minutes, after treatment, first use acetone to wash the treating agent residue on the surface of PTFE, and then clean with water, dry (indoor shade, can not be outdoor UV irradiation) can be glued. The waste treatment agent can be dumped after being treated with a small amount of ethanol to completely lose its black color. When a large amount of treatment agent is used, the residue should be neutralized by acid to neutral, and then dumped.