Expanded PTFE Tape is ideal for a wide range of applications. It is soft and pliable yet tough. It is physiologically harmless. It has no smell or taste. It is neither contaminating nor toxic. It is made using FDA approved raw materials Seals rough and irregular surfaces. Resistant against all chemicals from pH 0-14 – except molten alkali metals and elemental fluorine at high temperature and pressure.

The density:

It can be varied according to the actual application. Although the specific gravity of most ePTFE tapes is 0.7-0.8g/cm3, we are able to adjust its density according to the specific use environment of customers. In applications where ePTFE is sandwiched between steel elements, a high specific gravity would be more suitable. However, in precision applications, such as electronics and medicine, we may need to use gaskets or sealing elements, because the device itself is fragile and cannot apply large pressure. In this case, a low density tape is ideal as it can be formed into the desired shape with minimal pressure.

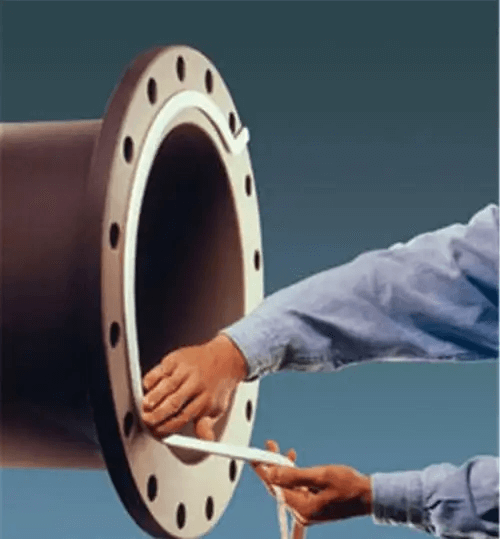

Expanded PTFE Gasket tape has a one-side adhesive bonding, which can be quickly pasted to the regular and irregular sealing plane, so as to achieve the ideal sealing effect. An adhesive strip on the back simplifies installation, especially on large heat exchangers or vertical flanges.

Sizes available:

| Thickness (mm) | Width (mm) | Length/Spool (m) | Note |

|---|---|---|---|

| 1.5 | 3.0 | 30.0 | Other sizes on request. Such as 5*2.5, 6*2.5, 6*3, 8*4, 9*5, 10*5, 12*5, 14*4, 15*3, 15*4, etc. |

| 2.0 | 3.0 | 30.0 | |

| 2.0 | 4.0 | 30.0 | |

| 3.0 | 5.0 | 25.0 | |

| 2.0 | 5.0 | 25.0 | |

| 2.5 | 7.0 | 20.0 | |

| 3.0 | 7.0 | 20.0 | |

| 3.0 | 8.0 | 10.0 | |

| 4.0 | 9.0 | 10.0 | |

| 3.0 | 10.0 | 20.0 | |

| 4.0 | 10.0 | 10.0 | |

| 4.0 | 12.0 | 6.0 | |

| 5.0 | 14.0 | 6.0 | |

| 5.0 | 16.0 | 3.0 | |

| 6.0 | 17.0 | 4.0 | |

| 7.0 | 20.0 | 5.0 | |

| 7.0 | 22.0 | 7.0 | |

| 8.0 | 25.0 | 5-10.0 | |

| 5.0 | 28.0 | 5-10.0 | |

| 5.0 | 30.0 | 5-10.0 | |

| 4.0 | 40.0 | 5-10.0 | |

| 4.0 | 50.0 | 5-10.0 | |

| 3.0 | 60.0 | 5.0 | |

| 3.0 | 70.0 | 5.0 | |

| 2.5 | 80.0 | 5.0 |

Technical Details:

- Temperature range: – 268°C up to +260°C, for short periods up to +310°C

- Density: 0.7-0.8g/cm³ (for rectangular cross-sections only)

- Colour: white

- Aging resistance: Itself does not age and is UV-resistant. However, the adhesive backing may lose its effectiveness if kept unused for too long;

- It is physiologically harmless. It has no smell or taste. It is neither contaminating nor toxic. It is made using FDA approved raw materials

How to use PTFE tape?

Clean and dry the sealing surface, select a PTFE tape of a certain width, tear off the protective paper of the adhesive tape, stick and press the PTFE elastic tape on the outer edge of the sealing surface, and the two ends overlap at a certain bolt, the intersection point The remaining 2cm or more (Note: when used on a flat flange, the two ends must be crossed and overlapped. When used on a grooved flange, they can be stacked in parallel and overlapped by more than 2cm.), close the corresponding sealing surface, and evenly When the bolts are tightened, the intersection of both ends will be pressed to the same thickness as other parts, and the intersection will never leak.